In cooperation with The Food Technology Department at the University of Life Science, SMARTTECH3D developed a new method of food quality evaluation. The variables registered during this process allow for the metric analysis and make fast comparison accessible. It is a significant progress in the meat quality control process, which significantly improves the methods of defining the technological values of meat.

The progressive idea for the meat quality evaluation

Increasing customers` expectations regarding the quality of bought products force the companies to pay extra attention to quality control. If conducted correctly, it will result not only in the growth of customer satisfaction, but also will affect the volume of waste generated in the process of production. It will also allow for introducing new beneficial solutions to the sales.

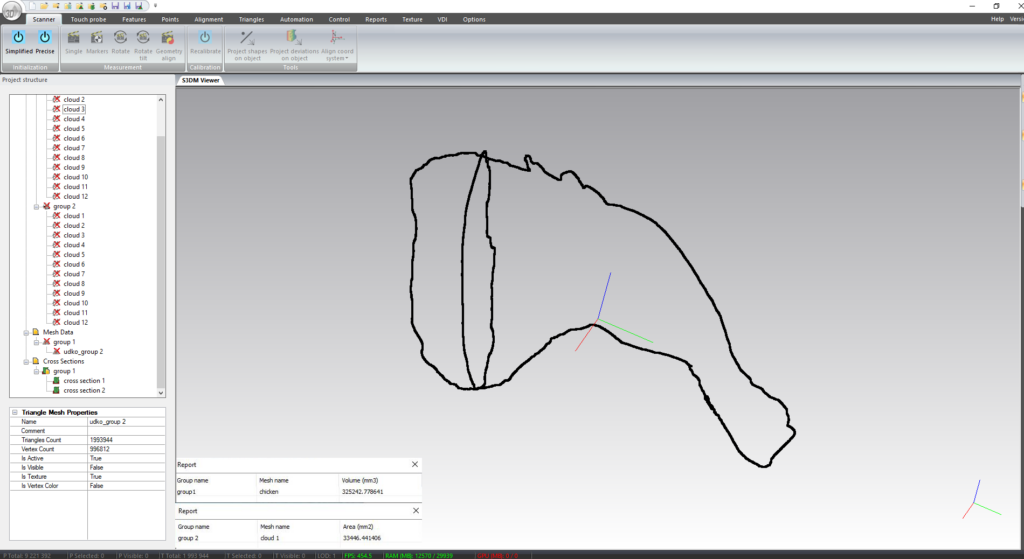

That’s why Food Technology Department at the University of Life Science started the research to create an effective quality control system. Its m main goal was to recognize the composition and the rank of chicken meat. Until now those parameters were determined by subjective assessment. For example, color was evaluated visually or instrumentally – colorimetrically (visual comparison of the product color and the color shown on the tester) or spectrophotometrically (a measure of the volume of the light transmitted or reflected by the product). All the measurements necessary to determine meat technological values were time-consuming and inaccurate. For example, mensuration of the meat volume was made by putting the meat sample in the glass cylinder filled with water. The level of liquid was read before and after putting the meat sample in. Introducing 3D scanners to quality control results in possibility to obtain more specific, precise data much faster. The measuring error of the meat volume is less than 2% with this method. Additionally, all the data is being automatically digitalized, so that it can be easily stored or sent for the purpose of further research.

One scan – perfectly accurate data

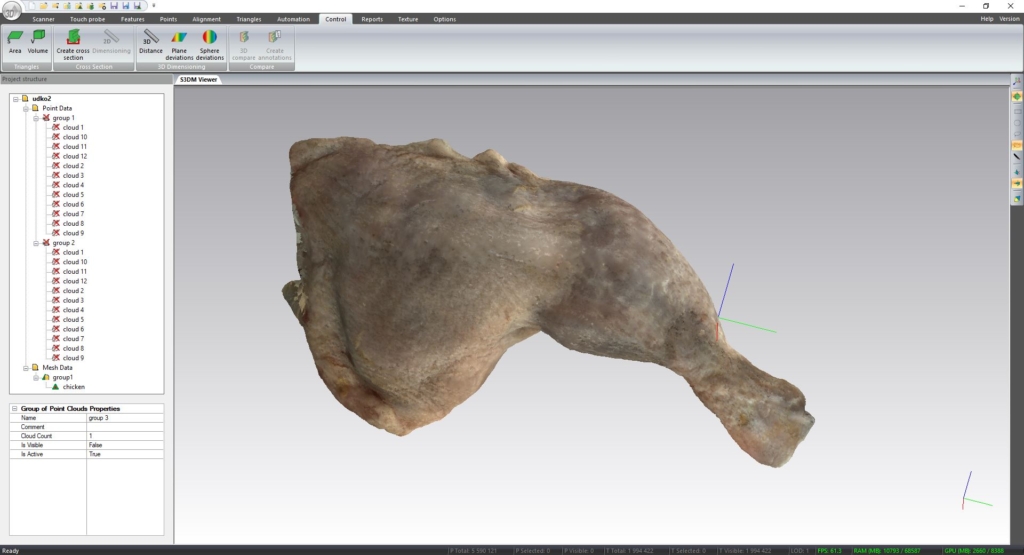

The equipment used in the research conducted by the Food Technology Department at the University of Life Science was SMARTTECH3D UNIVERSE 10 Mpix, with 400 x 300 x 210 mm field of view. The scanner is integrated with automatic shadeless lightning systems. The hardware allows for a perfect mapping of color and texture, which are incredibly important in meat quality control. As a result of the 3D scanning process, the colored cloud of points is generated, which allows for creation of the scanned object`s geometric model. That model is a precise representation achieved in few seconds. Many measurements can be performed on the obtained image, including precise cross-section dimensions (without actually cutting the meat sample) and volume calculations. The scanner used in the project flawlessly registers the texture and color, and SMARTTECH3Dmeasure software allows for the automatic percentage calculation of the meat surface with the same color. That is one of the most important indicators of the meat technological value.

Apart from collecting metric data, 3D scanning made the chicken meat classification much more efficient. That classification is based on what percentage of the chicken carcass is the breast. Currently, systematization depends on the weight, which is related to the size of different muscles, not only the breast itself. Those sizes vary significantly, which makes classification related to the weight not efficient – it can create a lot of waste if the breasts are not assigned to groups correctly. The wastage can generate high production costs. By using 3D scanners, a hygienic, touchless measurement of the chicken breast can be performed, without cutting the meat. The results of the 3D scan can determine the classification of the chicken meat.

The Food Technology Department at the University of Life Science recognized the research results as a success. It is planned to introduce 3D scanners to the other food quality control processes, in order to build a base for modern, efficient quality control procedures.