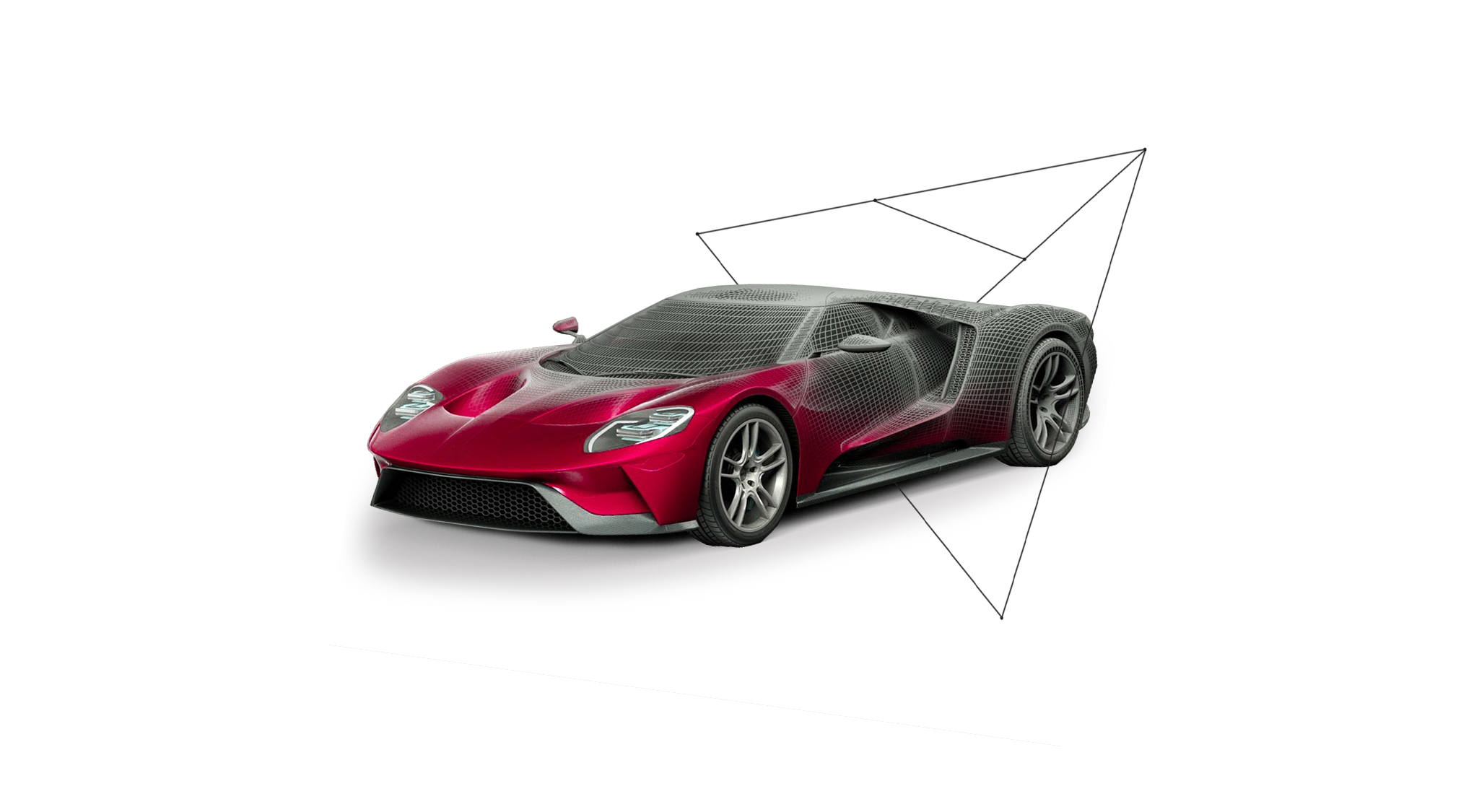

AUTOMOTIVE

The automotive industry requires a comprehensive solution from the supplier of an optical 3D scanner. Starting from engine design, inspection through external and interior design. It does not matter if you are involved in the creation of trucks, cars, motorcycles, or you are doing tuning or repairing your vehicle. Just as your clients require you to be fully professional, you may require us to do the same. We take responsibility for the success of any project that you use our equipment. Appropriately selected device and software will improve the quality of your work and significantly reduce time.

AEROSPACE

The aviation industry is one of the most demanding parts of the industrial market. Zero tolerance for all errors allows airline companies to guarantee safety and comfort. Understanding their requirements, we offer solutions that verify their strict requirements. Our scanners dedicated to the industry together with Geomagic modules are a comprehensive solution for the aviation industry. In this way, it not only speeds up work, but also reduces costs.

JEWELRY

The production of jewelry has entered a new era. All details made by punching, galvanizing, reposing, spinning and all other methods, just like different parts of the masterpiece, regardless of whether they are made in gold, silver, stone, precious stone, diamond or amber can be digitized by our devices. The largest resolution available on the market reflects the smallest detail with its natural color and gloss.

RAPID PROTOTYPING & REVERSE ENGINEERING

Rapid prototyping with a 3D optical scanner allows you to create detailed documentation of an existing object without modeling it in technical, industrial or graphic software. In the production process, 3D scanners also enable the construction of elements through 3D scanning. Thanks to the specialized software Geomagic or Leios, integrated with SMARTTECH 3D scanners, it allows you to generate fully compatible data in commonly used formats.

QUALITY CONTROL

The accuracy and high resolution of SMARTTECH 3D scanners provide ideal data for quality control and error detection. A large measuring field allows the control of large surfaces within a few seconds. The user can quickly and accurately check each part of the produced artifact during the production process directly from the production line. This is a great way to avoid unnecessary complications and faults. Each part leaving the factory is unified and free of errors.

HOW WE HELPED OTHERS FROM YOUR INDUSTRY

The 4th edition of the conference “3D scanning and printing technologies for industry and education” is behind us!

A conference was held on November 13 at the Central House of Technology at Krucza Street in Warsaw, the [...]

SMARTTECH3D in the aerospace industry

Aerospace and aviation have a reputation for holding vendors to incredibly high standards. The construction of flying machines brings together [...]

SMARTTECH 3D scanners in industry – “LUBIANA” porcelain factory

New 3D technologies are vital in many industries, departments, and fields all over the world. These technological advancements are popping [...]